The Best Pipe for Freezing Conditions: How CIPP Pipe Lining Ensures Year-Round Efficiency

Pipelining integrity is a way of ensuring infrastructure safety that has a major impact on the US economy. The leading cause of pipeline deterioration is environmental conditions, which lead to damage like corrosion, weak pipes, and eventually breaking down. So, what is the best pipe for freezing conditions? Let’s take a look at CIPP and find […]

Advantages of Epoxy Pipelining

Pipelines used for water supply, drainage, heating, and other applications are prone to damage due to constant exposure to corrosive chemicals. Such pipes need repair or replacement at some point. Epoxy coating offers a fast and convenient alternative to traditional excavation and replacement methods.

CIPP Pipelining vs Complete Pipe Replacement: What’s the Difference?

Many are unfamiliar with the term CIPP pipelining, even though it is a service that you may have to use for your business at some point. CIPP stands for cured-in-place pipe. This repair method is jointless and seamless and involves the use of an already existing pipe.

Complete pipe replacement is a method that pipelining professionals have used for decades. This method involves the placement of a completely new pipe. Although business owners have the comfort of knowing that they have a new pipe, there is also a higher expense because of the digging or trenching involved.

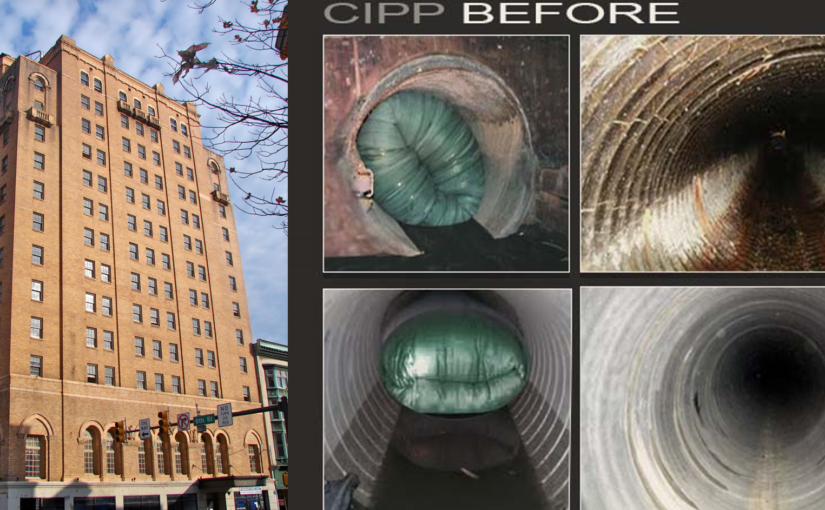

Cured-In-Place Pipe Lining Allows for Non-Invasive, Economical Restoration of Historic Landmark

An emerging leader in Cured-In-Place-Pipelining (CIPP), and trenchless lining solutions, US Pipelining, LLC., has completed a landmark restoration project at the historic Americus Hotel.

Expected to open in the summer of 2021 as part of the Wyndham Hotel Group’s Trademark Collection, the hotel will be the first of its kind in Pennsylvania. Erected on the site of the city’s first hotel/tavern known as the Northampton ca: 1810. The new and renamed Americus opened in 1927 attracting US Presidents, dignitaries, and visitors from across the country.

Refiner Pipelines More Secure Thanks to US Pipelining

Cured-In-Place Pipelining (CIPP) is the future of pipelining technology. As an emerging leader in Cured-In-Place solutions, US Pipelining, LLC., is highly specialized in the application and design of CIPP repair and restoration. Recently, US Pipelining completed a major refinery restoration in Delaware City, Delaware. This restoration comprised of CIPP rehabilitation to nearly 1500 linear feet of pipe with diameters ranging from 15 – 28 inches.

US PIPELINING LLC Completes Major Cured-In-Place-Pipe (CIPP) Restoration Project of Baltimore Harbor Tunnel Fire Suppression System

Philadelphia, PA – US Pipelining, LLC., an emerging leader in Cured-In-Place-Pipelining solutions (CIPP), announces the completion of project for the State of Maryland, Maryland Transportation Authority which included the Rehabilitation of the Baltimore Harbor Tunnel Fire Suppression Standpipes. The project called for the structural restoration of 14,000’ linear feet of pressurized standpipes within the Harbor Tunnel making up the tunnel’s fire suppression system. The project, which involved two phases including both the north and southbound chambers, was completed in September, 2020.

Case Study – Pressurized Pipe Restoration at famous “NASA Test Facility”

Where U.S. Pipelining is restoring a 24” diameter high temperature, high pressure intercondenser line in the In-Space Propulsion Facility (ISP) at NASA’s John Glenn Plum Brook facility. Using materials and resins designed to meet NASA specification, USP will install the project specific Cured-In-Place-Pipe (CIPP) within the facility’s intercondenser line.

Project of the Year 2017 Rehabilitation Runner Up: McGuire AFB ‘Largest CIPP Liner Ever Installed’

US Pipelining LLC recently completed a major military project that included the cured-in-place-pipe (CIPP) rehabilitation of nearly 1,000 lf of 10-ft diameter storm water piping located beneath the airfield apron of the McGuire Air Force Base in Burlington, New Jersey. As confirmed through Insituform, this is the largest CIPP liner ever installed.

“Working with our resin supplier, AOC, and our liner manufacturer, Manufactured Technologies Corporation (MTC), we were able to achieve something that, to the best of our knowledge, has never been attempted,” states Gary Horwedel, general manager of US Pipelining, who has been involved in infrastructure rehabilitation and repair using trenchless technologies for more than 25 years.

US Pipelining, LLC Completes Major Military CIPP Pipe Lining Rehabilitation Project

Philadelphia, PA – US Pipelining, LLC., an emerging leader in Cured-In-Place-Pipelining solutions (CIPP), announced today the completion of a major military project which included the cured-in-place-pipe rehabilitation of nearly one thousand (1,000’) linear feet of ten foot diameter (10’) storm water piping located beneath the airfield apron of the McGuire Air Force Base in Burlington, NJ. The over-the-hole installation of 10’ diameter CIPP liner is among the largest to have been successfully completed anywhere.